Our facilities provide casting, machining, and assembly of essential component parts for agriculture, construction, material handling, railroad, HVAC, and a host of other industries.

Superior casting capability based on 150 years of casting experience.

Transition from welding to casting to realize the following benefits:

- Reduced number of required components

- Reduced number of required secondary/assembly operations

- Reduced inventory complexity and costs

- Increased reliability of product performance

- Increased performance quality

- Reduced failure modes

Using ductile iron instead of aluminum results in the following benefits:

- Enhanced strength

- Longer part life

- Greater ductility

- Reduced risk of deformation

- Reduced risk of failure

Using austempered ductile results in:

- Reduced part weight

- Enhanced strength to weight ratios

- Enhanced toughness

- Improved elongation, competitive with steel

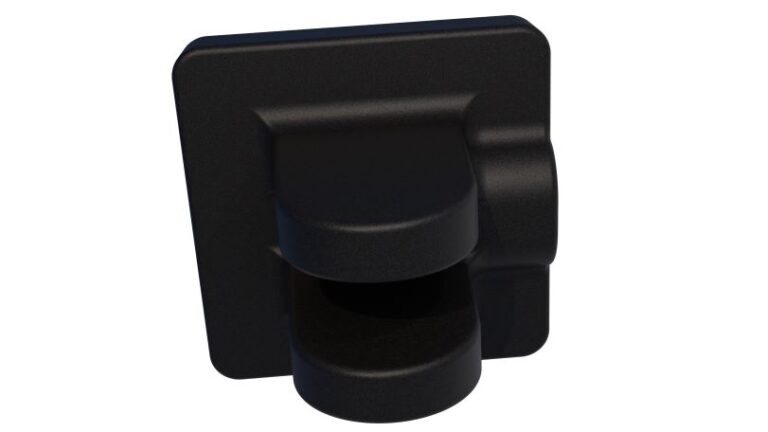

Protection. Control. Efficiency. Reliability.

Protection

- Safely houses components from impact and environmental elements

Precision control

- Maintain tight tolerances allowing for more efficient manufacturing and assembly processes that produce consistent parts

Reliability

- We supply quality castings that meet customer specifications day in and day out

- Reduced machining time

- Decreased scrap

- Reduced failure in the field

Expert material science capability

- NEI products are more consistent with machines due to the carefully selected material

- Machine cycle time is improved

- Extended life of cutting tools due to reduced tooling wear

Enhanced cooling system

- Improved hardness leading to enhanced reliability

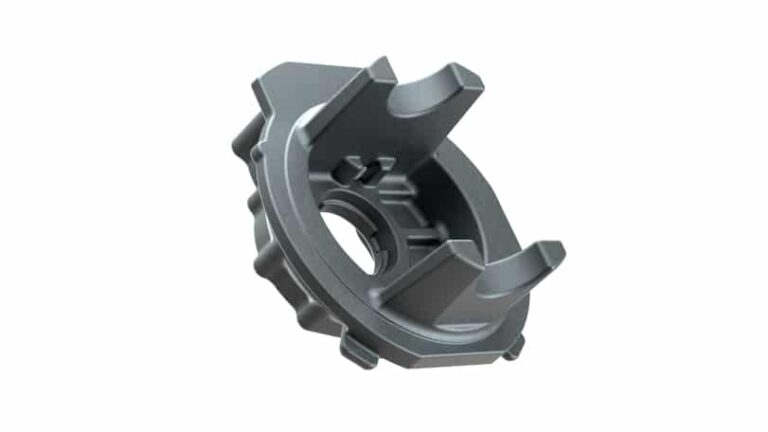

Outstanding Dimensional Stability. Reliability. Soundness.

Dimensional Stability results in:

- Enhanced manufacturing and assembly process efficiencies due to tighter tolerances

- Avoidance of interference

- Avoidance of failures

- Increased ease and convenience of machining and assembly operations

Expert metallurgy and material selection results in:

- Improved material performance in the field

- Enhanced ability to be consistent with the Brinell range for hardness

- Enhanced ability to control chemistries within tight tolerance ranges

- Improved ductility, impacting resistance and strength

- Increased machinability

High soundness or freedom from voids, shrinkage, and porosity, results in:

- Enhanced part strength

- Improved mechanical properties

- Reduced or eliminated fluid leakage

Dimensional Stability. Control. Reliability.

Dimensional stability results in:

- Enhanced manufacturing and assembly process efficiencies due to tighter tolerances

- Avoidance of interference

- Avoidance of failures

- Increased ease and convenience of machining and assembly operations

Expert metallurgy and material selection results in:

- Improved material performance in the field

- Enhanced ability to be consistent with the Brinell range for hardness

- Enhanced ability to control chemistries within tight tolerance ranges

- Increased machinability

Austempered ductile iron provides:

- Improved strength-to-weight ratio than aluminum

- Enhanced ability to match the lightweight of aluminum

- Improved strength and elongation, making it a great alternative to some steels

High soundness or freedom from voids, shrinkage, and porosity results in:

- Enhanced part strength

- Improved mechanical properties

- Reduced or eliminated fluid leakage

Precision control results in:

- Improved manufacturing and assembly process efficiency due to consistent tolerances; producing more consistent parts

Precision Control. Expert Material Science for Performance. Soundness.

Precision control results in:

- Enhanced manufacturing and assembly process efficiency due to tighter tolerances

Material science expertise results in:

- Improved material performance in the field

- Enhanced ability to be consistent with the Brinell range for hardness

- Enhanced ability to control chemistries within tight tolerance ranges

- Improved ductility impacts resistance and strength

- Better machinability and faster machining speed

- Increased CNC programming efficiency

- Enhanced tooling life

High soundness or freedom from voids, shrinkage, and porosity results in:

- Enhanced part strength

- Improved mechanical properties

Dimensional Stability. Expert Material Science for Performance. Soundness. Precision. Control.

Dimensional Stability results in:

- Enhanced manufacturing and assembly process efficiencies due to tighter tolerances

- Avoidance of interference

- Avoidance of failures

- Increased ease and convenience of machining and assembly operations

Expert metallurgy and material selection results in:

- Improved material performance in the field

- Enhanced ability to be consistent with the Brinell range for hardness

- Enhanced ability to control chemistries within tight tolerance ranges

- Improved ductility, impacting resistance and strength

- Increased machinability

Austempered ductile iron provides:

- Provides excellent wear properties

- Better strength to weight ratio than aluminum

- The ability to match the lightweight of aluminum

- Improved elongation, making it a great alternative to some steels

High soundness or freedom from voids, shrinkage, and porosity results in:

- Enhanced part strength

- Improved mechanical properties

- Reduced or eliminated fluid leakage

Precision control results in:

- Improved manufacturing and assembly process efficiency due to consistent tolerances; producing more consistent parts

Consistent weld quality with no variability.

Dimensional Stability. Expert Material Science for Performance. Soundness.

Dimensional Stability results in:

- Enhanced manufacturing and assembly process efficiencies due to tighter tolerances

- Avoidance of interference

- Avoidance of failures

- Increased ease and convenience of machining and assembly operations

Austempered ductile iron provides:

- Provides excellent wear properties

- Better strength to weight ratio than aluminum

- The ability to match the lightweight of aluminum

- Improved elongation, making it a great alternative to some steels

High soundness or freedom from voids, shrinkage, and porosity results in:

- Enhanced part strength

- Improved mechanical properties

- Reduced or eliminated fluid leakage

Expert metallurgy and material selection results in:

- Improved material performance in the field

- Enhanced ability to be consistent with the Brinell range for hardness

- Enhanced ability to control chemistries within tight tolerance ranges

- Improved ductility impact resistance, strength, yield, and elongation properties

- Increased machinability

- Reduced tooling wear